Description

Material: Alumina Ceramic

Color: white

Al2O3: ≥92%/95%/95%/ZTA

Mohs hardness: 9

HV hardness: 980/1040/1100/1250MPa

Bending strength: 260/280/320/350MPa

Compressive strength: 1150/1200/1250/1300MPa

Jet impingement abrasion: <0.47/0.42/0.28/0.1cm3

character: impact resistant ceramic

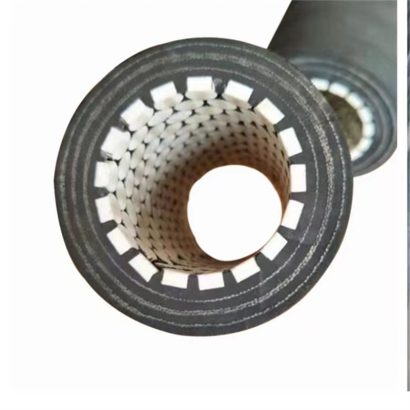

Hose Structure:

Inner rubber layer: NR + Ceramic sheet

Reinforcement: high-strength synthetic cord

Outer rubber layer: NR / SBR / BR

Working temperature : -20℃ to +100℃

Working principle:

High-quality wear-resistant ceramics are vulcanized inside the hose using an advanced vulcanization process. Multi-layer high-strength cords ensure that the pipeline has good compression resistance. It is not only very abrasion resistant, but also retains the soft characteristics of rubber tubes, and is generally used to isolate mechanical vibration or connect non-fixed equipment

Application:

Widely used in thermal power plants, cement plants, ore dressing plants, anti-corrosion chemicals, coal powder and slurry conveying systems, and also used in port and river dredging sand suction vessels, concrete pump trucks, etc.

Advantage:

- Wear resistance

The wear resistance of abrasion-resistant ceramic rubber hoses is more than 10 times that of ordinary steel pipes, and 20 times that of ordinary rubber pipes; - Corrosion resistance

Ceramic and high-quality anti-corrosion rubber can resist corrosion under harsh conditions; - Low running resistance

Lining ceramic is uniform, dense and smooth, which can reduce pressure loss and prevent the formation of eddy currents; - Impact resistance

The impact force on the ceramic is instantly buffered and absorbed by the rubber, so the wear-resistant ceramic rubber hose can withstand larger particle impacts; - Light weight

Weighing only 30% of steel pipes; - Flexible and flexible

The design and precise arrangement of the cylindrical ceramics in the rubber make the pipes have good flexibility, and the large-angle bending will not affect the ceramics; - Easy and fast installation

Provide a variety of connection methods such as fixed flanges, movable flanges, threads, and quick connectors.

| SIZE | OD | WP | BP | Weight | Length | |||

| mm | inch | mm | psi | bar | psi | bar | kg/m | m |

| 25 | 1″ | 47 | 150 | 10 | 450 | 30 | 1.9 | 20 |

| 32 | 1 1/4″ | 55 | 150 | 10 | 450 | 30 | 2.5 | 20 |

| 38 | 1 1/2″ | 62 | 150 | 10 | 450 | 30 | 3 | 20 |

| 51 | 2″ | 78 | 150 | 10 | 450 | 30 | 4.4 | 20 |

| 64 | 2 1/2″ | 91 | 150 | 10 | 450 | 30 | 5.3 | 20 |

| 76 | 3 | 106 | 150 | 10 | 450 | 30 | 6.7 | 20 |

| 102 | 4″ | 133 | 150 | 10 | 450 | 30 | 9.2 | 12 |

| 152 | 6″ | 186 | 150 | 10 | 450 | 30 | 12.9 | 12 |

| 200 | 8″ | 236 | 150 | 10 | 450 | 30 | 17.6 | 12 |

There are no reviews yet.